DuPont Kalrez O Rings

Gulf Chemical is the official Singapore distributor for DuPont Kalrez O Rings, DuPont Kalrez Bonded Door Seals and DuPont Kalrez VAT slit valve doors.

High Performance Perfluoroelastomer Parts

Kalrez® parts last longer and seal more effectively than other elastomers in demanding processing environments.

Kalrez® semiconductor processing seals are a field-proven choice for wafer-fabricating operations, including deposition, etch, ash/strip, thermal and wet-chemical processes.

Semiconductor Processing Seals For Field-Proven Contamination Control

Purity is critical to high wafer yield, and Kalrez® seals are designed with properties that help reduce contamination from particulates, outgassing and extractables.

Kalrez compounds for the semiconductor sector include:

| Product Name | Description |

| Kalrez® 1050LF | DuPont™ Kalrez® 1050LF perfluoroelastomer parts are a general-purpose product for O-rings, seals, and other parts used in chemical process industries. It has good hot water/steam resistance, excellent amine resistance, and good compression set properties. The maximum suggested service temperature is 288°C (550°F). It is not recommended for use in organic or inorganic acids at high temperatures. |

| Kalrez® 4079 | DuPont™ Kalrez® 4079 perfluoroelastomer parts are a low compression set product for general purpose use in O-rings, diaphragms, seals and other parts used in the chemical process and aircraft industries. It is a carbon black filled product with excellent chemical resistance, good mechanical properties, and outstanding hot air aging properties. It exhibits low swell in organic acids, inorganic acids and aldehydes, and has good response to temperature cycling effects. A maximum service temperature of 316°C (600°F) is suggested, with short excursions to higher temperatures possible. Kalrez® 4079 is not recommended for use in hot water/steam applications or in contact with certain hot aliphatic amines, ethylene oxide, or propylene oxide. |

| Kalrez® 6190 | DuPont™ Kalrez® 6190 perfluoroelastomer parts are a carbon black-filled product specifically designed for custom part and high volume applications. It has excellent thermal stability good mechanical strength properties and can be used in both static and dynamic sealing applications up to 300 °C (572 °F). In addition, Kalrez® 6190 is resistant to most chemical solvents but is not suggested for use in steam, strong acids or strong bases. Please contact a Kalrez® Application Engineer to discuss performance fit in your specific application. |

| Kalrez® 6375UP | To transform raw semiconducting materials into a useful device requires hundreds of chemical processing steps. A significant number of these steps involve aggressive acids, solvents, and bases (including amines) used to clean, rinse, etch or strip unwanted materials and contaminants from the wafer surface. These chemicals can attack elastomeric seals causing them to swell and degrade or to leach undesirable metallic and ionic extractables that affect integrated circuit functionality. |

| Kalrez® 7075UP | DuPont™ Kalrez® 7075UP perfluoroelastomer parts are a black product targeted specifically metal CVD applications. It offers outstanding thermal stability, very low outgassing and excellent compression set properties. Kalrez® 7075UP exhibits excellent seal force retention, has good mechanical properties and is well suited for both static and dynamic sealing applications. A maximum application temperature of 327°C (620°F) is suggested. Short excursions to higher temperatures may also be possible. Ultrapure postcleaning and packaging is standard for all parts made from Kalrez® 7075UP. |

| Kalrez® 8002 | DuPont™ Kalrez® 8002 perfluoroelastomer parts are a clear product for ash/strip applications. This unfilled product offers excellent plasma-cracking resistance and ultra-low particle generation in oxygen and fluorine-based plasmas versus mineral-filled products. Kalrez® 8002 exhibits excellent resistance to dry process chemistry, has good mechanical strength and is well suited for static, low stress/low sealing force and “select” bonded door seal applications. A maximum application temperature of 275°C (527°F) is suggested. Ultrapure post cleaning and packaging is standard for all Kalrez® 8002 parts. |

| Kalrez® 8085 | Kalrez® 8085 has been reported to significantly improve wafer production in a variety of semiconductor plasma process applications where oxygen and fluorinated plasmas are used during the cleaning cycle. |

| Kalrez® 8475 | Kalrez® 8475 perfluoroelastomer parts are a white product that have been specifically developed to meet the challenging requirements associated with lamp anneal and RTP sealing applications in semiconductor thermal processes. |

| Kalrez® 8575 | Kalrez® 8575 perfluoroelastomer parts are a white product for “select” etch, ash/strip and deposition process applications. |

| Kalrez® 8705 | DuPont™ Kalrez® 8705 perfluoroelastomer parts are primarily designed for seal locations in the direct path of high energy ultraviolet (UV) radiation emitted from a conventional light source or from plasma. |

| Kalrez® 8900 | Kalrez® 8900 perfluoroelastomer parts are a black product for all thermal processes, e.g., oxidation, diffusion furnace, metal CVD, ALD and LPCVD. It offers outstanding thermal stability, very low outgassing and excellent (low) compression set properties. |

| Kalrez® 9100 | Kalrez® 9100 is an amber translucent product targeted specifically for PECVD and HDPCVD processes. It has also exhibited excellent performance in “select” etch processes. |

| Kalrez® 9300 | DuPont™ Kalrez® 9300 perfluoroelastomer parts are a brown product for Dielectric (Oxide) Etch applications. It has been specifically designed for use in applications where the plasma environment is a combination of ions (“physical”) and radicals (“chemical”), i.e., where a balance of “physical” and “chemical” plasma erosion resistance is typically required. |

| Kalrez® 9500 | Kalrez® 9500 exhibits excellent resistance to CVD and ash/strip process chemistry, i.e., ozone, ammonia and water vapor. It also offers outstanding thermal stability, very low outgassing and excellent mechanical strength. |

| Kalrez® 9600 | DuPont™ Kalrez® 9600 perfluoroelastomer parts are designed for high purity, high temperature vacuum applications where seals are exposed to damaging Fluorine and Oxygen plasma radicals. |

| Kalrez® Spectrum™ 6375 | Kalrez® Spectrum™ 6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. |

| Kalrez® Spectrum™ 7075 | DuPont™ Kalrez® perfluoroelastomer parts are the material of choice for mechanical seals, valves, flanges and other demanding chemical and hydrocarbon processing applications. |

| Kalrez® Spectrum™ 7090 | Kalrez® Spectrum™ 7090 perfluoroelastomer parts are specifically targeted for use in applications requiring high hardness/higher modulus properties. |

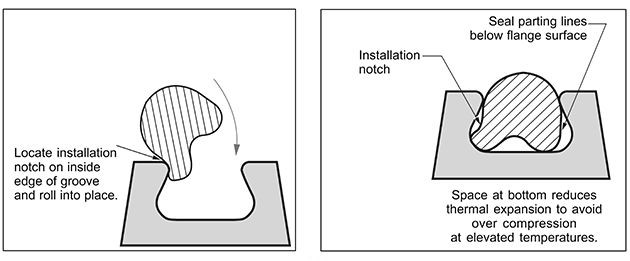

| Kalrez® TriLobe™ Seals | DuPont has developed a seal design to improve seal life in dovetail grooves. |

Semiconductor Processing Seals

Kalrez® seals for semiconductor processing are field-proven in the manufacture of semiconductor chips.

They can help extend planned maintenance intervals, and thereby lower long-term cost of ownership, in a wide range of semiconductor processes. In a number of fabrication customer evaluations, Kalrez®seals exhibited improved mechanical strength, lower particle generation and longer seal life versus competitive perfluoroelastomers, in both static and dynamic sealing applications.

Operations Improvements

Kalrez® seals can help improve semiconductor manufacturing in a range of wafer-fabricating operations, including:

- Deposition

- Etch

- Ash/strip

- Thermal

- Wet

Kalrez® TriLobe™ Seals

Kalrez® TriLobe™ Seals

DuPont has developed a unique seal design to improve seal life in dovetail grooves. This design benefits from the excellent chemical, thermal and plasma resistance of DuPont™ Kalrez® perfluoroelastomer parts with a unique cross-sectional trilobe seal that eliminates many of the problems associated with semi-dynamic seal applications using a dovetail groove. These problems include installation difficulties as well as short seal life and particle generation due to seal wear and degradation.

- Molded notch makes installation a snap

- Reduces installation time.

- Avoids improper installation.

- Geometry interlocks in groove to prevent seal from rolling and twisting during installation.

- Bottom lobes lock seal in place to resist pullout and movement during actuation.

- Seal parting lines are maintained below the flange surface, eliminating direct exposure to plasma or process chemicals.

- Seal design and compound selection combine to yield reduced particle generation and significantly increase seal life.

- Slit valve doors

- Gate valves

- Semi-dynamic sealing applications that utilize a dovetail groove configuration

- Molds have already been developed for a number of common slit valve door seal part sizes.

- A DuPont™ Kalrez® TriLobe™ seal can be developed to fit any size dovetail groove.

- The Kalrez® TriLobe™ seal is available in a variety of compounds.

Kalrez® Bonded Door Seals

Kalrez® Bonded Door Seals

Bonded door seals for gate valves and slit valve door seal applications provide improved sealing performance versus conventional O-rings by reducing particle generation, extending seal life and minimizing replacement time during preventive maintenance.

DuPont™ Kalrez® bonded door seals are designed for easy installation and low particle generation. They combine a custom seal design and proprietary adhesion technology along with the excellent plasma resistance of Kalrez® perfluoroelastomer seal materials developed for semiconductor applications. The seal is held in a “fixed” position versus conventional O-rings, thereby eliminating “rolling/twisting” and abrasion during door actuation. In addition, the seal design has been optimized using finite element analysis (FEA) to minimize high concentrations of localized stresses. As a result, both particle generation and sealing performance are significantly improved versus conventional O-rings.

Bonded door seals replace O-ring seals currently used in gate valve, and slit valve dovetail grooves in particle sensitive semiconductor etch, ash, strip and/or deposition processes.

Lower Particle Generation and Extended Seal Life versus Conventional O-rings

- Sealing element held in a “fixed” position, i.e., eliminates “rolling/twisting” in service

- Design eliminates O-ring abrasion against edge of dovetail groove during actuation/compression

- Kalrez® semicon product grades used to minimize particle generation in reactive plasmas

- Kalrez® Ultrapure™ post-cleaning and packaging reduces unwanted contamination

- Improved sealing performance—optimal design minimizes high concentrations of localized stresses

Less Replacement Time Versus O-ring Seals During Preventive Maintenance

- Quick and easy assembly/disassembly to mounting hardware

- Reduces installation problems commonly experienced with O-ring seals

- Eliminates need to clean the seal gland during preventive maintenance

- Barcode on packaging plus bonded door seal part number and Kalrez® product number engraved on back of commercially available bonded door seals enables traceability and identification providing assurance that it is a Kalrez® perfluoroelastomer part (FFKM).

DuPont™ Kalrez® bonded door seals are available for a number of valve types used in semiconductor OEM equipment platforms. In addition, a custom Kalrez® bonded door seal can be developed for most gate valve and slit valve door applications if not currently available. Kalrez® UltraPure™ post cleaning and packaging is standard for all bonded door seals.

Gulf Chemical stocks Kalrez parts and services wafer fabrication plants across Singapore and Malaysia. Please contact us for a proposal and quotation at order@gulfchem.com.sg